The global development history of Metal Injection Molding (MIM) dates back to the late 1960s and early 1970s. Several key milestones mark the evolution and maturation of this technology

Origins Phase (Late 1960s to Early 1970s):

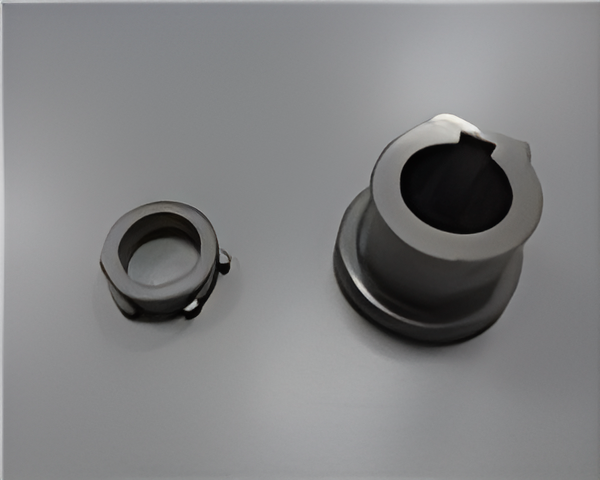

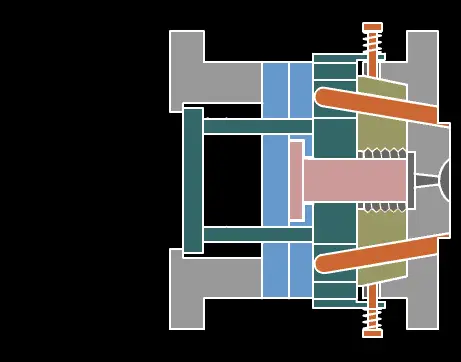

Metal Injection Molding (MIM) technology first emerged in the United States and Europe, primarily used for producing small metal parts such as watch components, automotive parts, and tool components.

During this phase, MIM technology was in its infancy, facing various technical challenges such as powder formulation, molding processes, and equipment technology.

Development Phase (1980s to 1990s):

In the 1980s and 1990s, with technological advancements and process improvements, MIM technology gradually developed and gained popularity.

The introduction of new materials and powder formulations enhanced the applicability and versatility of MIM processes, enabling the production of a wider range of parts.

During this phase, MIM technology began to be widely applied in industries such as automotive, electronics, and medical, emerging as a promising new manufacturing technology.

Maturity Phase (Early 21st Century to Present):

Since the early 21st century, with the rapid development of global manufacturing and technological advancements, MIM technology has entered a mature phase.

Continuous refinement and innovation have significantly improved product quality and production efficiency in MIM processes.

Simultaneously, MIM technology has found applications in more sectors, including aerospace, defense, and energy, becoming an advanced manufacturing technology with broad prospects and potential.

conclusion

Metal Injection Molding (MIM) has evolved over decades from an emerging manufacturing technology to a mature and widely applied advanced manufacturing technology, playing a significant role globally. Its ongoing technological advancements and expanding applications indicate further development and potential for MIM technology in the future.