MIM Materials

Common MIM Materials

Due to the high density of MIM parts, their properties match those produced by other fabrication methods. MIM offers great flexibility in material selection, as the same equipment can be used to produce parts from different metal materials. Moreover, a wide range of metals can be utilized in MIM processes.The properties of MIM parts are determined by the chemical composition, particle sizes, and shapes of the metal powder used. In summary, our MIM materials are categorized as follows:

Ferrous Alloys

- Steel

- Stainless Steel

- Tool Steel

- Low Alloy Steel

- Iron-Nickel Alloy

- Special Ferrous Alloys like Invar and Kovar

Tungsten Alloys

- Tungsten-Copper

- Tungsten Heavy Alloys

Nickel Alloys:

- Nickel

- Nickel-Base Superalloys

Molybdenum Alloys:

- Molybdenum

- Molybdenum-Copper

Hard Materials

- Cobalt-Chromium

- Cemented Carbides (WC-Co)

- Cermet (Fe-TiC)

Specific Materials:

- Aluminum

- Precious Metals

- Copper and Copper Alloys

- Cobalt-Based Alloys

- Magnetic Alloys (Soft and Hard)

- Shape-Memory Alloys

Stainless steel

JunKun MIM Materials

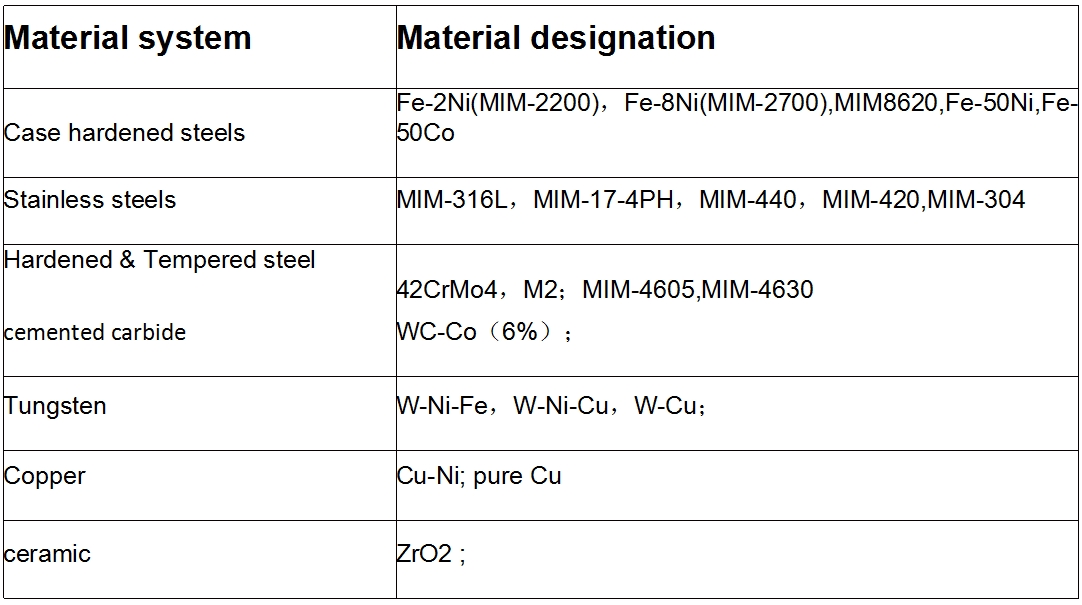

You can check our common MIM materials as following graph.

Custom MIM Materials

Most alloy compositions are derived from standard handbook formulations. However, it’s crucial to acknowledge that the long-term annealing in the sintering process can degrade alloy properties, given that most alloys were initially designed for and developed in casting technology. Therefore, at JunKun, we employ a modified chemistry approach to MIM technology, in order to guarantee the physical and chemical properties, of MIM parts.

Such as 316L alloy composition (Fe-19Cr-9NI-2Mo) is wildly applied in reason of its corrosion resistance and combined strength properties. Otherwise, extra chromium in the alloy composition will make the sintering process easier, so this alloy provides attainable superior properties with this alternative metal manufacturing method.

Custom metal powder can be fabricated at an additional cost once the composition is unavailable. There is no doubt that we can meet your material needs at the most cost-effective price.