General Introduction

Analysis of the Difficulty in Machining Titanium Alloys

Titanium alloys possess certain characteristics that make them more challenging to machine. Here are some reasons why titanium alloys are difficult to machine:

1. High strength and low thermal conductivity: Titanium alloys have high strength and low thermal conductivity, requiring higher cutting forces and more complex cutting tools during machining, which increases the difficulty of machining.

2. Reactivity: Titanium alloys react with elements such as oxygen and nitrogen in the air at high temperatures, forming oxides and nitrides. This reaction leads to increased tool wear and decreased surface quality during the cutting process.

3. Low coefficient of thermal expansion: Titanium alloys have a low coefficient of thermal expansion, making them prone to deformation and residual stress during machining. Proper measures need to be taken to control deformation and stress.

4. High-temperature cutting: Due to the high melting point and hardness of titanium alloys, cutting is typically performed at higher temperatures, which increases machining costs and difficulty.

5. Tool selection and cooling during cutting: Choosing the appropriate tool material and lubricant is crucial for reducing tool wear and improving surface quality. Additionally, effective cooling systems are required to control machining temperatures due to the high thermal conductivity of titanium alloys.

In summary, the high strength, reactivity, low coefficient of thermal expansion, and high-temperature cutting characteristics of titanium alloys are the main reasons why they are difficult to machine. Machining titanium alloys requires specialized equipment and processes, as well as appropriate measures to overcome the challenges encountered during machining.

Typically, titanium alloy sintering does not require carbon-based binders. Due to the high chemical reactivity of titanium alloys, especially at high temperatures, using carbon as a binder may lead to reactions between carbon and titanium, resulting in carbide formation and affecting the final product’s performance. Therefore, in the sintering process of titanium alloys, non-carbon or low-carbon binders are usually used to avoid this problem, ensuring the quality and performance of the final product.

Titanium alloy sintering typically requires dedicated furnaces. Due to the high melting point and reactivity of titanium alloys, strict control of temperature and atmosphere conditions is required during the sintering process to ensure the quality and performance of the final product. Dedicated furnaces typically have precise temperature control systems and special atmosphere control devices, capable of providing a high-temperature inert atmosphere environment suitable for titanium alloy sintering, to prevent oxidation or other adverse reactions of titanium alloys during sintering. Therefore, to achieve optimal sintering results, titanium alloys are usually sintered in dedicated furnaces.

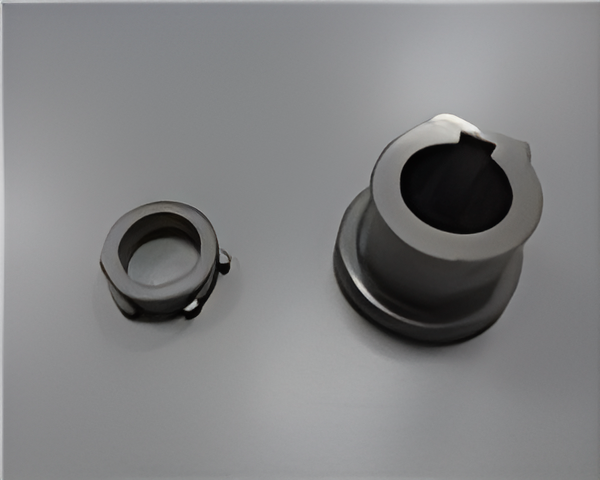

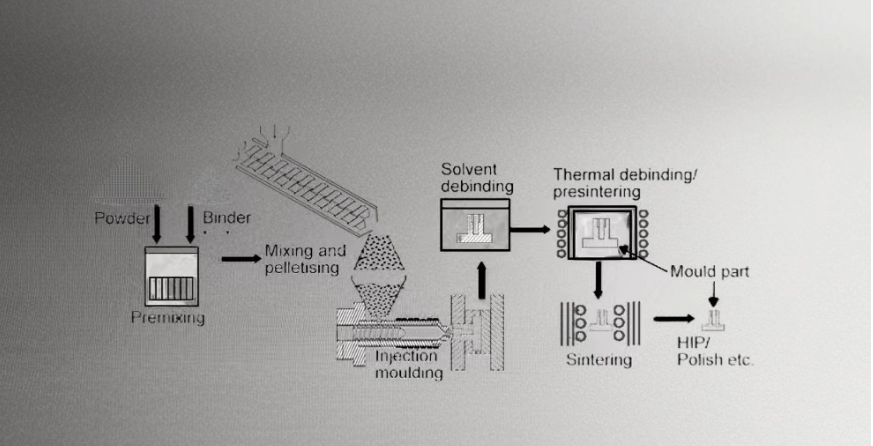

Summary: With the development of technology and equipment, the titanium alloy Metal Injection Molding (MIM) process is now quite mature in the market. Through metal powder injection molding technology, high-precision parts with complex geometries, including those made of titanium alloys, can be produced. The MIM process has been widely used, especially in the automotive, aerospace, and medical device fields. With continuous process improvement and technological development, titanium alloy MIM processes have made significant progress in production efficiency, product quality, and cost control, thus holding a considerable mature position in the market.

Factors Affecting the Surface Sintering Quality of Titanium Alloy

1. Temperature Control: Temperature control during the sintering process is a crucial factor affecting surface quality. Ensuring that the sintering temperature reaches an appropriate level promotes bonding between metal particles and ensures surface quality.

2. Atmosphere Environment: The atmosphere during sintering also plays a vital role in surface quality. Inert atmospheres (such as argon or nitrogen) are commonly used during sintering to prevent oxidation and maintain surface quality.

3. Sintering Time: Proper sintering time is another key factor in ensuring surface quality. Too short sintering times may result in incomplete sintering of the surface, while excessively long sintering times may lead to over-sintering and grain growth.

4. Initial Powder Quality: The quality of the metal powder used initially also directly impacts the surface quality of the final product. High-quality metal powder can produce a more uniform structure and better surface quality.

5. Sintering Pressure: In some cases, appropriate sintering pressure can also affect surface quality, helping to ensure tight bonding between metal particles.

In summary, surface sintering quality depends on multiple factors, and it is necessary to strictly control and optimize these factors throughout the entire sintering process to ensure that the final product has the desired surface quality.

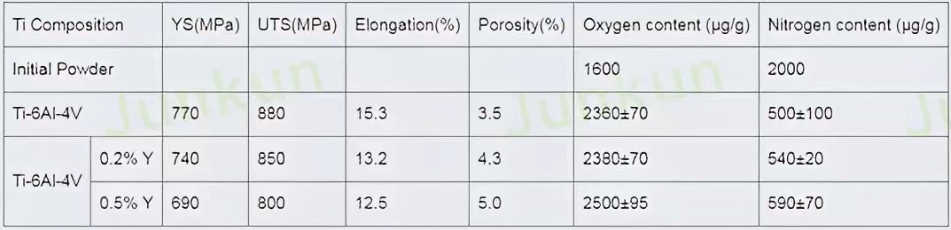

Common Titanium MIM Alloy Materials and Their Physical Properties Introduction

Common MIM (Metal Injection Molding) titanium alloy materials are typically Ti-6Al-4V alloy, which mainly consists of:

1. Titanium (Ti): As the primary base metal, it provides excellent strength and corrosion resistance.

2. Aluminum (Al): Enhances the hardness and strength of the alloy.

3. Vanadium (V): Improves the strength and heat resistance of the alloy.

Ti-6Al-4V alloy exhibits excellent physical properties, including:

1. High strength: Ti-6Al-4V alloy has a good strength-to-weight ratio, making it stronger than many other metals.

2. Outstanding corrosion resistance: The alloy possesses excellent corrosion resistance and can be used stably in harsh environments for extended periods.

3. Good biocompatibility: Ti-6Al-4V alloy finds widespread use in the medical field due to its good biocompatibility with human tissues, minimizing rejection reactions.

4. Lightweight: Compared to many other metals, titanium alloy has a lower density, making it advantageous for applications in aerospace and other fields.

5. Good machinability: Despite titanium alloy’s challenges in machining, proper processes and equipment can effectively machine it.

In summary, Ti-6Al-4V alloy is a versatile material with excellent physical properties, particularly suitable for applications requiring high strength, corrosion resistance, and biocompatibility, such as medical devices, aerospace, etc.

Comparison of MIM Titanium Alloy Components with Other Processes

MIM (Metal Injection Molding) titanium alloy components offer several advantages compared to other processes:

Cost-effectiveness: MIM technology can often produce complex-shaped titanium alloy parts at a lower cost compared to traditional machining processes. By optimizing production processes and minimizing material waste, MIM achieves cost-effectiveness, especially in large-scale production.

Complex geometries: MIM technology enables the production of titanium alloy parts with intricate geometries, such as internal cavities, threads, and fine details. Compared to traditional machining processes, MIM achieves these complex shapes with higher precision and fewer processing steps, reducing production costs and increasing efficiency.

High material utilization: MIM technology achieves high material utilization by mixing metal powders with binders and injecting them into molds. This means that there is minimal waste generated during the production process, reducing material costs.

Excellent surface quality: Titanium alloy parts manufactured by MIM typically exhibit excellent surface quality, meeting high application requirements without the need for additional surface treatments. This makes MIM an ideal choice for producing high-quality titanium alloy parts.

High production efficiency: MIM technology is suitable for large-scale production, capable of producing a large number of titanium alloy parts in a short time. Compared to traditional machining processes, MIM generally offers faster production cycles and higher production efficiency.

In summary, MIM titanium alloy components offer lower cost, higher production efficiency, superior surface quality, and greater design freedom compared to other processes, making them the ideal choice for producing high-quality titanium alloy parts with complex shapes.

Titanium Alloy Surface Treatment

Titanium alloy surface treatment involves various processes aimed at enhancing the surface properties of titanium alloy components for specific applications. Some common surface treatments for titanium alloy include:

1. Anodizing: Anodizing is a widely used surface treatment for titanium alloys, which involves creating a controlled oxide layer on the surface through an electrochemical process. This oxide layer improves corrosion resistance, wear resistance, and provides decorative finishes.

2. Passivation: Passivation is a chemical process that removes surface contaminants and forms a protective oxide layer on the titanium alloy surface. This process enhances the corrosion resistance of the material and improves its biocompatibility in medical and dental applications.

3. Electroplating: Electroplating involves depositing a layer of metal (such as gold, silver, or nickel) onto the titanium alloy surface through an electrolytic process. This improves the surface properties, such as wear resistance, conductivity, and aesthetics.

4. Thermal spraying: Thermal spraying involves applying a coating of metallic or ceramic material onto the titanium alloy surface using heat and pressure. This process improves surface hardness, wear resistance, and thermal insulation properties.

5. Polishing and buffing: Polishing and buffing are mechanical processes that smooth the titanium alloy surface and remove imperfections, scratches, and roughness. This enhances the surface finish, aesthetics, and cleanliness of the components.

6. Surface modification: Surface modification techniques, such as plasma treatment, laser surface modification, and ion implantation, are used to alter the surface properties of titanium alloys, such as hardness, adhesion, and biocompatibility, to meet specific application requirements.

Overall, titanium alloy surface treatment plays a crucial role in improving the performance, durability, and functionality of components in various industries, including aerospace, automotive, medical, and marine applications.

Select a Professional Manufacturer for Your Needs

Ready to unlock the potential of TiMIM Manufacturing for your next project? Get in touch with us today to discover how our advanced TiMIM technology can bring your designs to life with unparalleled precision, strength, and efficiency. Let’s revolutionize your metal component production together. Contact us now to discuss your requirements and get started!