Definition

unlocking new possibilities in the production of high-precision parts.

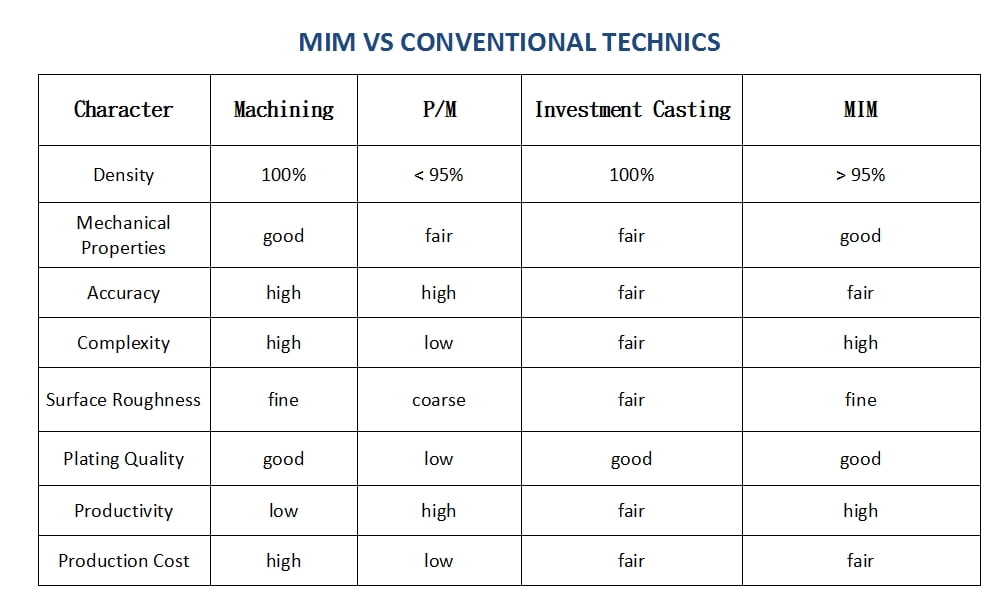

At its core, MIM harnesses the power of fine metal powders, thermoplastic, and wax binders. This unique blend undergoes a meticulous compounding process, resulting in a homogenous pelletized feedstock. What sets MIM apart is its ability to use this feedstock in an injection molding process akin to plastic, achieving unparalleled density and precision over large production runs.

Features And Advantages Of MIM Parts:

Forming advantages

The geometric shapes of MIM parts have high degrees of freedom, enabling one-step production of complex-shaped metal components.

Thin-walled Products:

Wall thicknesses less than 10 millimeters are well-suited for MIM, although thicker outer walls can also be accommodated. However, abrupt changes in wall thickness should be avoided. We can achieve products with extremely thin walls down to 0.2mm (though this depends on specific product shapes).

Wide Range of MIM Materials Selection

The applicable of MIM materials is wide, with broad application fields. High raw material utilization rate, high degree of production automation, simple processes, capable of achieving continuous large-scale production.

Hard Metal and High Melting Point Metal

MIM technology enables the shaping of intricate components from challenging materials with high melting points, like Cobalt Alloys, Tungsten Alloy, and Tool Steel. This capability unlocks fresh avenues for crafting high-performance parts that may prove difficult to manufacture using conventional methods.

Weight

MIM is suitable for components weighing less than 100 grams, with less than 50 grams being the most common application. Raw material is a key cost factor in the MIM process. During the initial stages of MIM product design, efforts are often made to minimize component weight as much as possible. Similar to plastic products, weight reduction of components can be achieved through cores and ribs without compromising product integrity. MIM excels in extremely small and micro parts, with limits reaching weights less than 0.1 gram, such as micro gears.

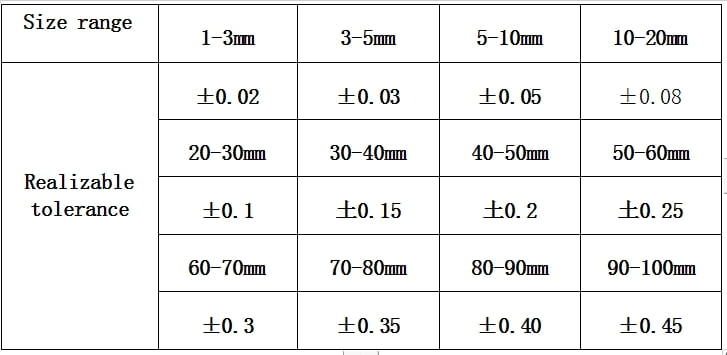

High Tolerance Product accuracy

Metal Injection Molding (MIM) part tolerances are nominally ±0.3%-0.5%, although tighter tolerances can be achieved in some cases if deemed essential. MIM component production ranges over a large size range, making it difficult to address tolerances directly over such a wide range. In some instances, the choice has been to create a table of tolerance versus size, showing capabilities as follows: These tolerances can be obtained within a single batch but wider variation is usually observed over time.

Convenient Post-manufacturing

Unlike standard powder metallurgy, which achieves 80-90% of theoretical density, MIM triumphs with an impressive 95-100%. This translates to closer tolerances, reduced costs, and the ability to produce small, intricate parts at scale.

Feedstock Creation: Very fine metal powders are intricately mixed with thermoplastic and wax binders, forming a homogeneous pelletized feedstock. This feedstock mirrors the characteristics of plastic and allows for injection molding.

Molding Magic: The feedstock is subjected to heat and injected into a mold cavity under high pressure. This enables the production of intricate shapes with shorter cycle times. The resulting component, known as the “green part,” maintains the final geometry but is about 20% larger to accommodate shrinkage during sintering.

Debinding Dance: The green part undergoes a controlled debinding process, removing the binders and transitioning it to the “brown” stage. This phase is crucial in preparing the part for the final sintering step.

Sintering Sorcery: In the sintering phase, the brown part is exposed to temperatures nearing the material’s melting point. This process eliminates remaining binders, granting the part its ultimate density and strength.

MIM Product development process

Product Design

Mold design

MIM product development

MIM Volume production

Choosing MIM for Manufacturing Success

As a Metal Injection Molding (MIM) supplier with 17 years of experience, we provide comprehensive services from design to production:

Consultative Design Service: Our material and design engineers are available from the project’s inception to offer free advice on material selection, process optimization, and structural design.

Mechanical Design And Data Replication: Based on your product requirements or existing samples, we conduct mechanical design and create detailed production drawings for seamless replication.

Rapid Prototyping: Utilizing CNC machining, 3D printing, and rapid molding, we offer rapid prototyping services for testing and validation.

On-demand Manufacturing: We offer on-demand customization with no minimum order quantity requirement, allowing you to minimize initial product development costs.

Simplified Assembly And Testing: Our capabilities include basic hardware assembly such as soldering, fastening, and snap-fit assembly. We also conduct prototype testing, including size and tolerance analysis, fit and form testing, as well as durability and wear testing. Contact Shanghai JunKun team now to confirm whether your new design is MIM part?