描述

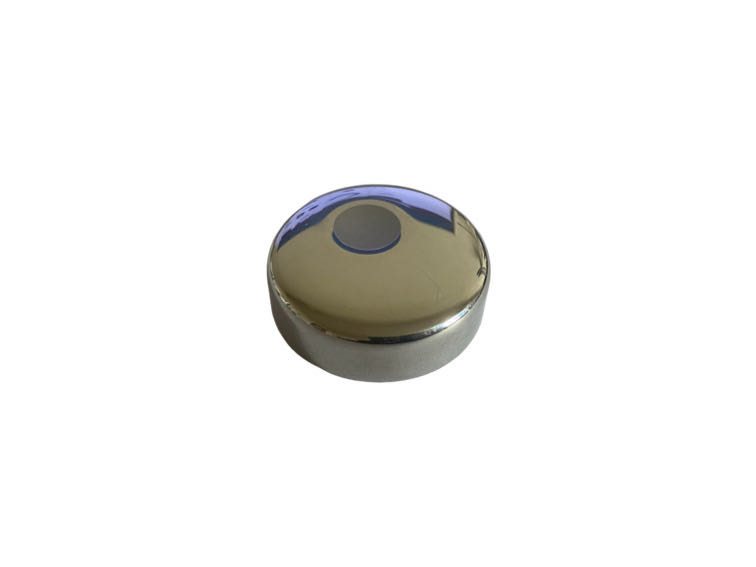

Material: 316L Stainless Steel

Surface Treatment:Polishing

Household Application MIM Parts are precision-engineered components manufactured using Metal Injection Molding (MIM) technology, specifically designed for various household applications. These parts are versatile and offer several advantages over traditional manufacturing methods.

One of the key materials used in producing these MIM parts is 316L stainless steel. This material is known for its excellent corrosion resistance, making it suitable for applications in household environments where exposure to moisture and chemicals is common. Additionally, 316L stainless steel can be mirror polished to achieve a smooth and reflective surface finish, enhancing the aesthetic appeal of the parts.

The MIM process allows for the production of complex geometries with high precision, ensuring that the household parts meet exact specifications and fit seamlessly into their intended applications. Compared to conventional manufacturing techniques like machining or casting, MIM offers cost-effective production with minimal material waste, making it an ideal choice for mass production of household components.

From kitchen utensils to bathroom fixtures, household appliances to decorative items, MIM parts made from 316L stainless steel can provide durable, corrosion-resistant solutions that enhance the functionality and appearance of various household products.