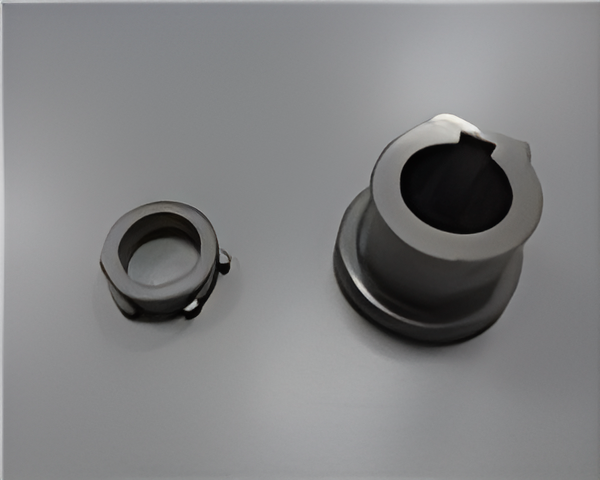

MIM and PM, as two powder-based metal processing methods, are used for manufacturing metal parts.

The two techniques are suitable for producing small metal products with high quality. Manufacturers worldwide are adopting these technologies to produce high-quality metal components with complex geometries.

They prefer the freedom to design components without sacrificing cost. Traditional methods are no longer able to meet these special requirements, thus new molding processes like MIM and PM have become the solution. These advanced processes can produce metal parts with high tolerances, superior surface finishes, and specific properties.

Overview of Metal Injection Molding (MIM) and Powder Metallurgy (PM)

Metal injection molding is a unique metal processing technology that stands out for its excellent thin-wall processing capabilities. Compared to other machining methods, MIM is the only technology capable of effectively handling metal parts with thicknesses as thin as 0.1 millimeters.

The superiority of this technology makes MIM the preferred choice for products requiring lightweight design and complex geometries. It achieves high precision in small structures and fine dimensions, providing a wider range of design possibilities and application prospects for products in various industries.

MIM’s uniqueness lies in its innovative injection molding process, which allows multiple parts to be fused into a single component. This integrated manufacturing approach not only simplifies the assembly process but also greatly enhances production efficiency.

By consolidating multiple parts into one, MIM reduces the number of assembly steps and time required, as well as lowering the fitment requirements between parts, further enhancing manufacturing consistency and precision. This highly efficient production method makes MIM the preferred machining method in many industries, particularly suitable for products requiring highly integrated and complex components.

MIM harnesses the power of fine metal powders, thermoplastic, and wax binders. This unique blend undergoes a meticulous compounding process, resulting in a homogenous pelletized feedstock. What sets MIM apart is its ability to use this feedstock in an injection molding process akin to plastic, achieving unparalleled density and precision over large production runs.

Powder Metallurgy (PM)A. Process Overview

Initially, metal powders of suitable particle size are chosen and then placed into molds, where pressure is applied to compact the powder. Subsequently, the compacted powder is sintered at high temperatures to fuse the metal powder particles together, achieving the desired density and mechanical properties.

Over Comparison Analysis

Cost analysis:

From a cost-effectiveness perspective, PM compaction molding may be a cost-effective solution for simple parts. However, if clients seek cost savings with higher-density, higher-complexity components despite investing in more expensive raw materials and equipment, MIM injection molding can achieve this goal.

The metal powders employed in MIM typically have finer particle sizes, ranging from 2 to 15 micrometers, whereas powder metallurgy utilizes coarser metal powders, typically ranging from 50 to 100 micrometers.

As a result, the powders used in MIM are more expensive than those used in powder metallurgy. This difference directly affects the forming performance of the process and the density of the final products. Due to the smaller particle size used in MIM, it can more densely fill the mold, resulting in higher product density and finer part structures.

In contrast, powder metallurgy products tend to have lower densities.

Complexity Comparison:

The powder metallurgy (PM) process relies on high-pressure uniaxial pressing, resulting in shapes mostly in the form of 2D cylinders, making it more suitable for relatively simple structural components.

In contrast, Metal Injection Molding (MIM) allows for virtually no geometric limitations, offering highly flexible three-dimensional design possibilities. MIM consolidates individual sub-components into a single MIM part (see illustration).

MIM parts exhibit uniform wall thickness. Non-uniform thickness can lead to distortion, internal stresses, voids, cracks, and indentations, as well as uneven shrinkage, affecting dimensional tolerances and control.

weight reduction:

“Taking a core,” commonly known as “coring” in metal injection molding (MIM) or other molding processes, refers to designing a cavity or hole in a part to facilitate material injection. This helps create internal voids or channels within the part to meet specific functional requirements or reduce its weight.

On the other hand, “weight reduction” involves reducing the weight of a part while maintaining its functionality and performance through specific process or structural adjustments.

Part assembly feature:

MIM-manufactured parts typically exhibit precise dimensions and shapes, allowing for easy assembly with other components.Therefore, these parts can fit well with other components, facilitating a smoother overall assembly process. Whether it’s holes and slots, burrs, or threads, MIM-manufactured parts can ensure good fit and match with other components, thus achieving a more stable and reliable assembly.

Surface Appearance:

MIM enables intricate detailing on part surfaces, including fluting, lettering, and logos, enhancing their appearance and adding personalized features to products. Therefore, during MIM manufacturing process, parts can be customized with surface treatments as needed to meet various design requirements from customers.

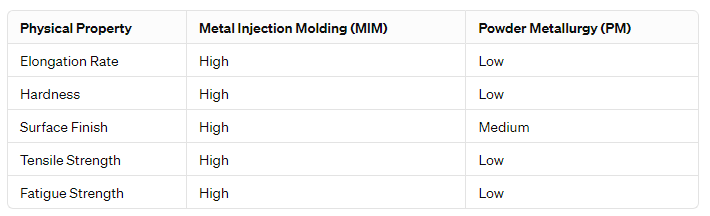

Comparison of Key Physical Properties:

| parameters | MIM | PM |

|---|---|---|

| Density | >94-98% | <93%(Max) |

| Particle Size | 2-15 micron (μm) | 50-100 micron (μm) |

| Cost | Medium | Low |

| Miniaturization | High | Medium |

| Design Flexibility | High | Medium |

| Thin-wall Capability | High | Medium |

| Quantity | Good | Poor |

| Material Range | High | High |

| Operability | High | High |

| Weight | 0.1-200 g | 1-1,000 g |

| Dimensional Tolerance | High(0.2-0.5%) | High(0.1-2.0%) |

Ideal for Intricate Shapes:

The use of MIM injection molding has virtually no geometric limitations, offering highly flexible three-dimensional design.

For components with complex geometric shapes, MIM is more cost-effective than PM.

Sintering Temperature:

The sintering temperature for the same alloy material differs. The higher sintering temperature in MIM production increases manufacturing costs. However, we need to consider other returns:

High precision: MIM technology uses small-sized powders and high-temperature sintering, resulting in higher design tolerances compared to PM.

High density: The higher sintering temperature leads to more metal powder melting, eliminating surface porosities in the process. Therefore, MIM parts have higher density than PM parts.

Surface finish: The surface finish of MIM parts can reach 1 micron, superior to PM.

High corrosion resistance: Due to the high density and refined surface of MIM parts, their corrosion resistance is higher than that of PM parts.

High fatigue strength: The high-temperature sintering process enhances the metal’s fatigue strength. Thus, MIM parts of the same material outperform PM parts.

Cost-effective Manufacturing

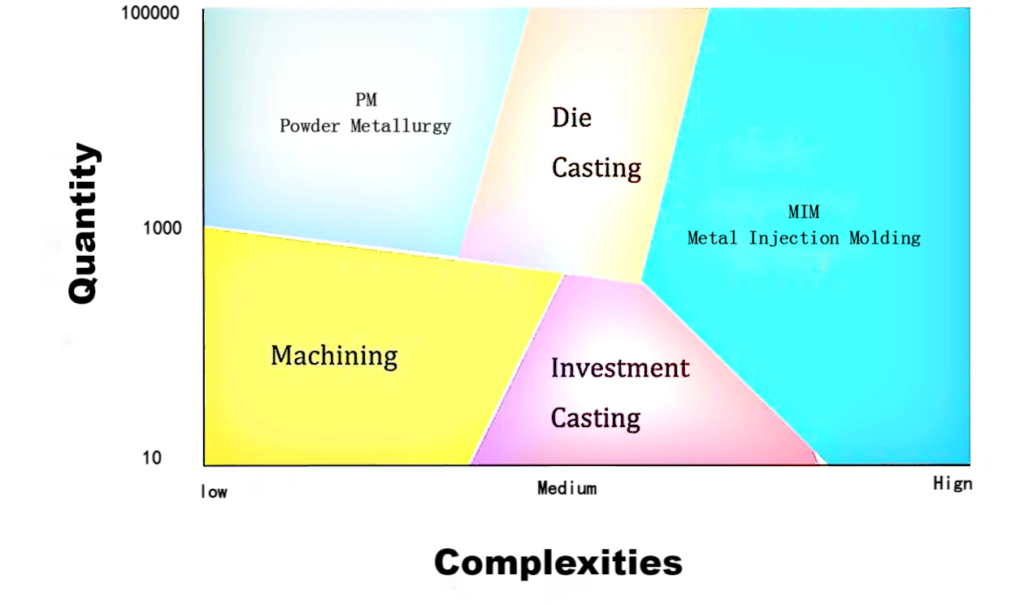

Volume & Complexity:

In the diagram below, we should consider the complexity and volume of the part to choose the most economical processing method. PM can only meet the requirements of simple shape parts, however MIM can achieve complex geometric shapes.

MIM Manufacturing Advantages

- Cost Efficiency: MIM manufacturing offers cost efficiency, especially for large-scale production, by reducing labor and waste while enhancing material utilization. This cost-effectiveness makes it suitable for various industries, including medical, automotive, and electronics.

- Complex Geometries: MIM excels in producing parts with intricate shapes and features that would be difficult or impossible to achieve with traditional manufacturing methods. Its ability to replicate complex geometries accurately allows for the creation of high-precision components.

- High Strength and Density: MIM parts exhibit high density and mechanical strength, comparable to those produced by traditional machining methods. This ensures that MIM components meet rigorous performance requirements across different applications.

- Surface Finish and Consistency: MIM parts boast excellent surface finish and consistency, making them suitable for applications where aesthetics and precision are critical. The process enables the production of parts with smooth surfaces and tight tolerances, ensuring uniformity and quality in the final products.

Professional MIM Part Supplier

We have the capability for independent material feedstock development, allowing us to customize and optimize alloy formulations according to customer requirements

With nearly 20 years of production experience, we have continuously refined our process and improved production efficiency, ensuring product quality and timely delivery.

Our dedicated team of engineers, technicians, and quality control experts provides comprehensive technical support and service to our customers, ensuring smooth production processes and meeting customer needs.

To learn more about MIM technology and our manufacturing services, please don’t hesitate to contact us. Whether you need customized parts, technical consultation, or a quotation, our professional team is ready to support you. Reach out to us today to discuss your project requirements and find the best solution together.