Metal Injection Molding VS Machining: A Comparative Analysis

Introduction

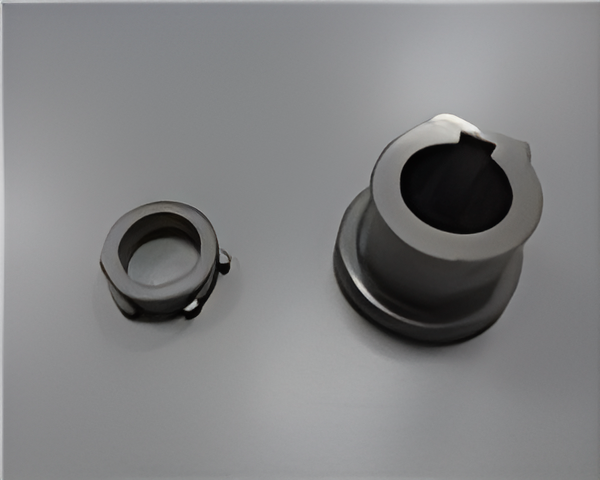

MIM: A process of metal production that is highly effective, involves combining metal powder with a binder, then molding it, and finally sintering to create intricate metal components.

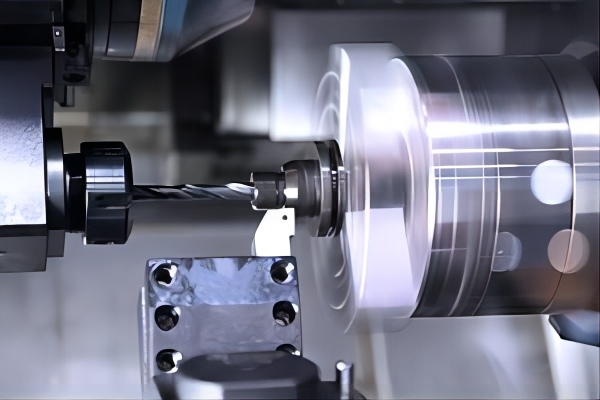

CNC Machining: Traditional metal processing methods, including milling, turning, drilling, etc., which involve material removal to achieve the desired shape and dimensions.B. Stating the Purpose and Importance of Comparative Analysis

Through the comparative analysis of MIM and machining, to explore their differences in cost, manufacturing cycle, precision, applicability, etc., and provide better decision-making basis for manufacturers and engineers.

Similarities

MIM parts and CNC parts share similarities in several aspects. Firstly, both can achieve high-precision manufacturing, producing components with complex geometries and precise dimensional requirements. Secondly, both are applicable to various types of materials, allowing them to meet the needs of different industries and applications. Lastly, both can facilitate batch production, catering to the demands of mass production. Therefore, MIM parts and CNC parts share similarities to a certain extent.

Key Distinguishes

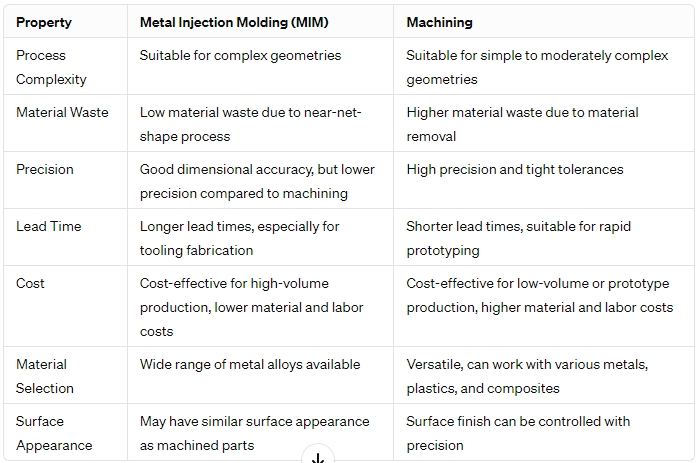

The comparison between Metal Injection Molding (MIM) and Machining reveals several differences, which can aid in selecting the optimal method for your specific project demands

Cost Comparison:Metal Injection Molding (MIM) typically incurs lower costs, especially in large-scale production, as it reduces labor and waste while improving material utilization. In contrast, machining tends to be higher in production costs, particularly for complex parts.

Manufacturing Cycle:MIM generally requires longer manufacturing cycles due to multiple processes involved, including mold making, injection molding, debinding, and sintering. In comparison, machining typically has shorter manufacturing cycles as it is a direct processing method without additional steps.

Tolerances. Comparison:

MIM and CNC machining are common manufacturing methods, but they differ in terms of tolerances.

MIM typically achieves high tolerances, usually ranging from 0.3% to 0.5% of the dimension.

CNC machining can achieve very precise tolerances, often reaching levels as low as 0.01 millimeters.

Tolerances in CNC machining can be adjusted as needed, making it suitable for various projects and requirements.

In summary, while both MIM and CNC machining can meet precise tolerance requirements, CNC machining typically offers more flexibility and precision in tolerance control.

Applicability And Material Range Comparison: MIM is suitable for producing parts with complex shapes and high precision requirements and can use various metal materials, including steel, stainless steel, iron, nickel alloys, and titanium alloys. In contrast, machining can handle a wider range of materials, including metals, plastics, and composites, but may not be as applicable for complex geometries as MIM.

Summary of the Advantages and Disadvantages of MIM and CNC Machining:

Metal Injection Molding (MIM):

Advantages:

- Suitable for producing complex-shaped and high-precision parts.

- Capable of achieving high precision and complexity with good surface finish

- Lower cost, especially in mass production.

Disadvantages:

- Longer manufacturing cycle, involving multiple processes such as mold making, injection molding, debinding, and sintering.

- Tolerance issues may arise for larger-sized parts.

CNC Machining:

Advantages:

- Shorter manufacturing cycle, suitable for rapid part production.

- Capable of handling various materials with high precision and flexibility.

- Suitable for parts of various sizes and shapes.

Disadvantages:

- Higher cost, especially for manufacturing complex parts.

- Requires experienced operators and specialized equipment.

Recommendations for Choosing the Appropriate Manufacturing Method

Recommendations for Choosing the Appropriate Manufacturing Method in Specific Contexts:Choosing the right manufacturing method is crucial based on project requirements and specific circumstances.

For projects requiring the production of complex-shaped and high-precision parts, MIM may be the preferred choice, especially for cost reduction in mass production.

Conversely, for projects requiring rapid production and lower costs, CNC machining may be more suitable, especially for small-batch production or situations requiring flexibility.

Considering project requirements, cost, and time factors, selecting the most suitable manufacturing method can ensure smooth project execution and optimal results.

Summary

Through the comparative analysis presented in this article, we gain a clear understanding of the similarities and differences between Metal Injection Molding (MIM) and machining, along with their respective advantages and disadvantages.

MIM is suitable for producing complex-shaped and high-precision components, offering cost advantages but with longer manufacturing lead times, whereas machining is preferred for rapid production and handling a wider range of materials albeit at relatively higher costs.

When selecting the appropriate manufacturing method, it is crucial to consider various factors including project requirements, costs, and time constraints to ensure optimal manufacturing outcomes.

Delving deeper into the principles and applications of these manufacturing methods will facilitate making informed decisions in real-world projects, leading to superior manufacturing results.