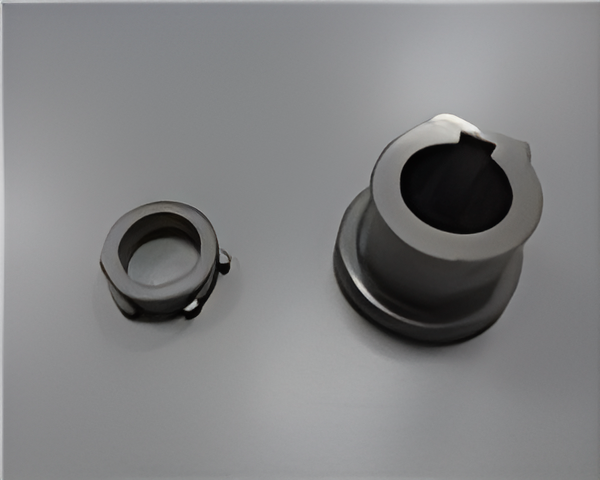

Metal Injection Molding (MIM) is an efficient and economical method that produces high-density, complex structural parts, notably in sewing machine production. Using the rotary hook as an example, MIM saves over 200 processes compared to traditional methods, significantly reducing production time, labor, and energy costs. Specifically, 20 workers can produce 300,000 rotary hook blanks monthly, a task requiring thousands traditionally. Overall, MIM can cut labor costs by 80% and total costs by at least 20%.

Comparison of Traditional Machining Process and MIM for Rotary Hook

In the manufacturing process of a sewing machine’s rotary hook, two common methods are used: traditional machining process and Metal Injection Molding (MIM) technology. Let’s compare these two manufacturing methods to better understand their respective advantages, disadvantages, and suitable applications

Traditional Process

Process Steps:

- Material Preparation: In the traditional manufacturing process, raw materials are commonly used. This involves steps such as cutting and heat treatments.

- Manufacturing Process: Mechanical equipment such as lathes and milling machines are used for cutting to complete the manufacturing and shaping of the product.

- Surface Treatment: The product undergoes polishing and plating processes to enhance surface quality and corrosion resistance.

Advantages:

- The manufacturing process is mature and equipment is widely used.

- It can be applied to various metal materials and complex shape manufacturing.

Disadvantages:

- The manufacturing cycle is long, resulting in low production efficiency

- There is significant cutting loss, leading to low material utilization

- Multiple processing steps are required, resulting in higher costs.

Process steps:

- Material Preparation: This is the first step of the MIM process, which mainly involves mixing metal powder with a binder. This mixture is prepared into MIM feedstock through granulation and other processes, ready for the next step of injection molding.

- Injection Molding: At this stage, the MIM feedstock is injected into a mold. Through high-pressure injection molding, we can form a near-net-shape rotary shuttle blank. This process is very precise, requiring accurate control of injection pressure and time.

- Sintering : Sintering is a key step in the MIM process. In this stage, the injection molded blank is placed in a sintering furnace and sintered at a high temperature. High-temperature sintering causes the metal powder particles to bond together, forming a dense metal part.

- Post-processing: The sintered parts need to be post-processed, including surface treatment, polishing, and other processes, which can improve the surface quality and durability of the parts.

Advantages of the MIM process:

- It can achieve high-precision, complex shape manufacturing, which makes MIM widely used in the production of precision parts.

- The MIM process has a short production cycle and high production efficiency, and can quickly produce a large number of parts.

- The MIM process has high material utilization and low loss, which means it is an environmentally friendly manufacturing technology.

- The MIM process uses injection molding, which is a simple process, requires low mold requirements, has a low cost, and has high molding accuracy and a low scrap rate.

- In the MIM process, because the injection-molded blank has a uniform texture and high precision, there is no stress deformation during sintering, and no complex support structure is needed. This greatly simplifies the process, saves steps, and reduces costs.