Introduction of Copper injection molding

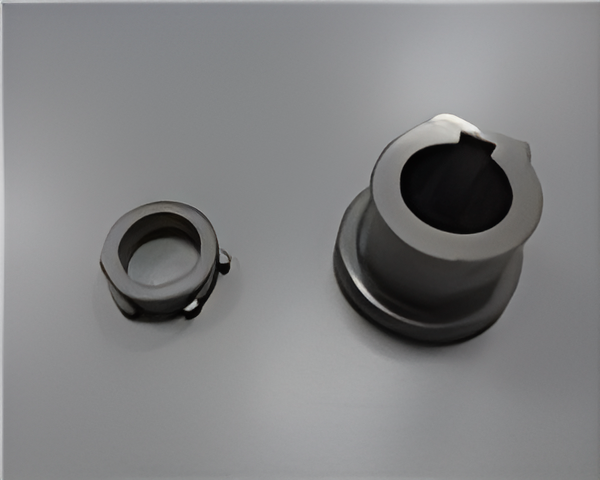

Copper Injection Molding (CuMIM) is an advanced technology predominantly used for manufacturing high-complexity Heat Dissipation Components like heat sinks at a reduced cost. Leveraging copper’s exceptional thermal and electrical conductivity, this method enables the production of intricate shapes, particularly useful in the electronics and automotive industries.

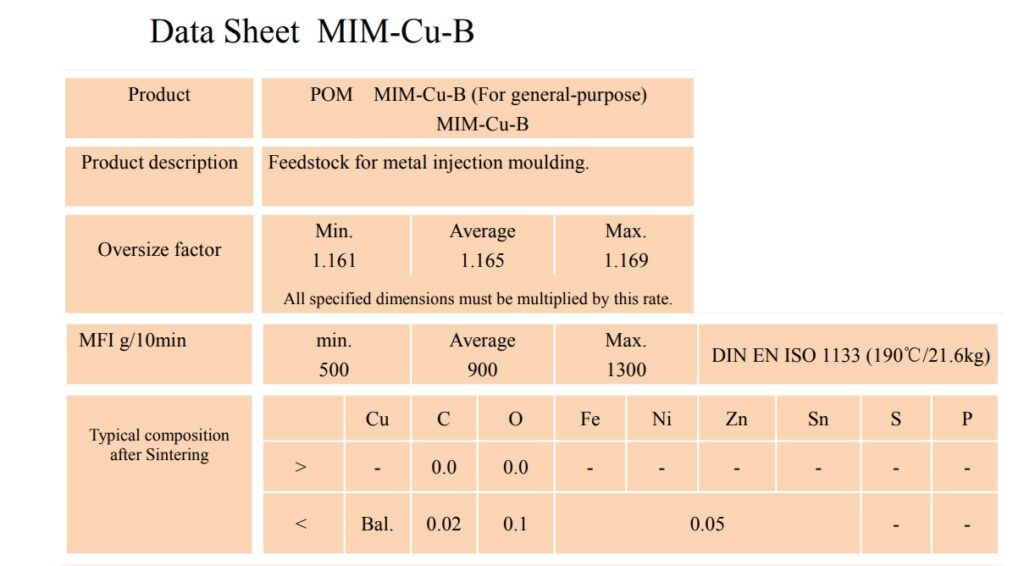

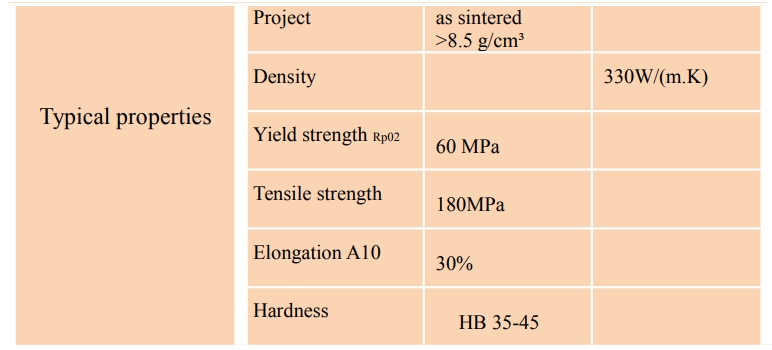

Typical Chemical Composition

Mechanical properties (Sintered Part)

MIM Copper: Basic Principles and Process

Basic Principles:

Metal Injection Molding (MIM) is an efficient manufacturing technology used to produce complex-shaped metal parts. The basic principle of MIM Copper is similar to traditional MIM processes but involves specific characteristics and processing methods for copper material. Essentially, the manufacturing process of MIM Copper includes mixing fine copper powder with polymer powder and other additives to form an injectable paste-like mixture. This mixture is then injected into molds and sintered at high temperatures to form copper parts.

Process Overview:

- Raw Material Preparation: Fine copper powder is mixed with polymer powder and other additives according to a specific recipe. These additives control the shrinkage rate and material flowability during sintering.

- Injection Molding: The mixture is injected into molds with desired shapes. The molds typically consist of two parts that accommodate the shape of the mixture and produce mirrored parts.

- Debinding: After injection molding, the parts undergo debinding to remove the polymer. The debinding process usually occurs at high temperatures to ensure complete polymer decomposition and removal.

- Sintering: The debound parts are placed in high-temperature furnaces for sintering. During sintering, copper powder particles are fused together to form dense copper parts.

- Post-Processing: Sintered parts may require post-processing operations such as surface treatment, polishing, or heat treatment to achieve the desired surface quality and performance.

Conclusion:

The basic principles and process of MIM Copper are similar to traditional MIM processes but require special attention to the characteristics and processing parameters of copper material. MIM Copper technology provides an efficient method for manufacturing complex-shaped copper parts with high precision, excellent surface quality, and outstanding mechanical properties, suitable for various application fields.

Commonly UsedMIM Copper Alloy Materials Introduction

Copper is a pliable and ductile metal renowned for its softness and exceptional thermal and electrical conductivity. Some commonly used copper alloy materials in Metal Powder Injection Molding (MIM) include:

- Brass: A blend of copper and zinc.

- Bronze: A mixture of copper and tin.

- Tungsten-Copper: Combination of copper and tungsten.

Pure Copper:

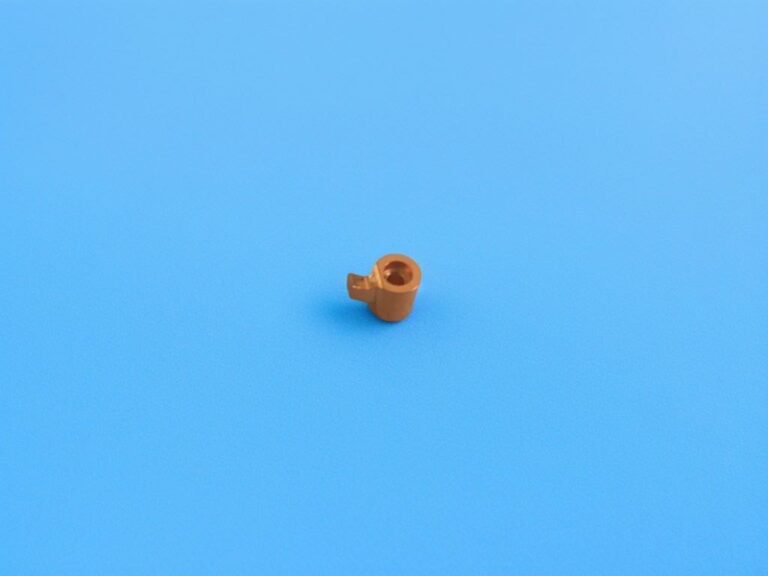

MIM technology enables the production of complex-shaped copper parts for connectors, sockets, and other electrical components.Pure copper in MIM technology is an ideal material for unconventional designs in electronic, automotive, and optical-electronic applications. CuMIM, using pure copper material, produces components with 320 W/mK thermal conductivity and enables complex geometries

Brass (CuZn):

Brass MIM (CuZn MIM)Brass is an alloy of copper and zinc, with different ratios yielding varying colors and properties in terms of mechanics, electrical conductivity, acoustics, and chemistry. Additionally, brass alloys contain trace amounts of arsenic (As), lead (Pb), phosphorus (P), aluminum (Al), manganese (Mn), and silicon (Si).

Characteristics: Properties of BrassBrass possesses a lower melting point, excellent workability, durability, and outstanding electrical and thermal conductivity. Brass with higher copper content tends to be softer and exhibits a deep golden color, while brass with lower copper content tends to be harder and has a silvery-white appearance. By adjusting the proportions of copper and zinc, the hardness of brass can be modified.

Application Of Brass MIM

Brass Metal Injection Molding (MIM) boasts exceptional corrosion resistance, conductivity, and strength. It is a highly malleable metal suitable for the manufacture of intricate geometric shapes. The unique appearance, ease of processing, and wear resistance of brass make it widely applicable in various industries, including construction, electronics, and automotive. Furthermore, brass is a recyclable material, contributing to environmental sustainability and resource conservation.

Bronze:

Bronze is a copper-tin alloy known for its strength, wear resistance, and corrosion resistance. MIM bronze parts are used in bearings, bushings, and automotive components.

Tungsten-Copper:

Combination of copper and tungsten,An alloy of tungsten and copper is used to counteract heat-induced expansion, with the degree of expansion customizable by adjusting the tungsten to copper ratio. A higher tungsten ratio results in less expansion, while a greater copper ratio induces more expansion.

Advantages of CuMIM:

- Complex Geometries: CuMIM technology allows for the production of complex-shaped parts, including intricate structures and internal channels, meeting various application requirements.

- Material Savings: CuMIM technology maximizes the utilization of raw materials, reducing waste and material consumption, improving production efficiency, and reducing costs.

- High Precision: CuMIM parts exhibit high precision and excellent surface finish, meeting strict requirements for dimensions and surface quality.

- Material Selection: CuMIM technology can be used with various metal materials, including copper and its alloys, providing designers with more material choices and design flexibility.

Applications of CuMIM in Different Industries:

- Electronics Industry:CuMIM technology is used to manufacture heat sinks, connectors, and conductive components in electronic products, improving product performance and reliability.

- Automotive Industry: CuMIM parts are used in high-temperature and high-pressure applications in automotive engines and transmission systems, enhancing the wear resistance and corrosion resistance of automotive components.

- Medical Equipment: CuMIM technology is used to manufacture surgical instruments, implants, and catheters in the medical industry, meeting the requirements for material purity and biocompatibility.

- Aerospace Industry: CuMIM parts in the aerospace sector include aircraft engine components, spacecraft devices, and aviation electronic equipment, offering advantages of lightweight and high strength.

- Conclusion: Understanding the advantages and applications of CuMIM technology highlights its importance and potential in the manufacturing industry. With continuous technological development and expanding application scope, CuMIM will continue to bring more innovation and development opportunities to various industries.

Choose A Reliable MIM Suplier For Success

As a Metal Injection Molding (MIM) supplier with 17 years of experience, we provide comprehensive services from design to production:

Consultative Design Service: Our material and design engineers are available from the project’s inception to offer free advice on material selection, process optimization, and structural design.

Mechanical Design And Data Replication: Based on your product requirements or existing samples, we conduct mechanical design and create detailed production drawings for seamless replication.

Rapid Prototyping: Utilizing CNC machining, 3D printing, and rapid molding, we offer rapid prototyping services for testing and validation.

On-demand Manufacturing: We offer on-demand customization with no minimum order quantity requirement, allowing you to minimize initial product development costs.

Simplified Assembly And Testing: Our capabilities include basic hardware assembly such as soldering, fastening, and snap-fit assembly. We also conduct prototype testing, including size and tolerance analysis, fit and form testing, as well as durability and wear testing.

Contact Shanghai JunKun team now to confirm whether your new design is MIM part?