What is 440C Stainless Steel

Stainless steel 440C is a high-carbon grade of chromium stainless steel known for its exceptional hardness, wear resistance, and corrosion resistance. It finds wide applications in the manufacturing of premium cutting tools, bearings, pneumatic valves, molds, and various other fields. With its chemical composition including elements like carbon, silicon, manganese, phosphorus, sulfur, chromium, and molybdenum, 440C steel offers superior performance in demanding environments.

MIM 440C Stainless Steel

When 440C stainless steel is mentioned, people often think of its high hardness and excellent wear resistance. However, precisely because of its extreme hardness, processing 440C material becomes quite challenging, especially for products requiring intricate shapes. Traditional machining methods may become exceedingly difficult.

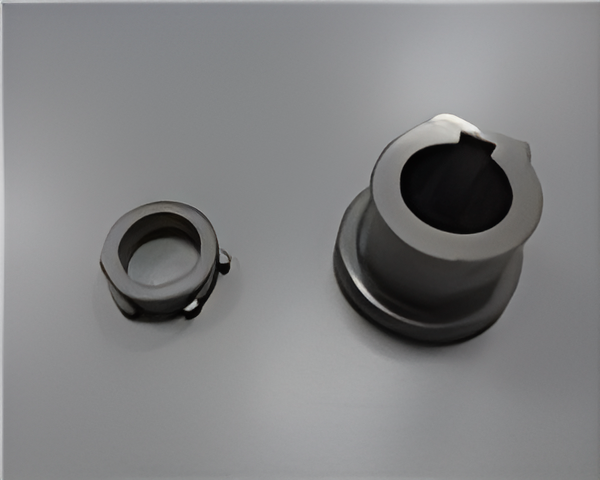

MIM (Metal Injection Molding) is the preferred processing solution for small, three-dimensional, complex-shaped 440C material parts.

Metal injection molded parts made from martensitic 440C stainless steel deliver outstanding hardness, strength, and corrosion resistance, achieving hardness levels surpassing HRC 60.

Properties of MIM 440C Stainless Steel

440C Stainless Steel Equivalent Grades

Advantages of 440C Stainless Steel MIM Parts

Cost-Effectiveness:

Metal injection molding combines the advantages of traditional metal processing and plastic injection molding, making it easy to produce various complex-shaped metal components. For high-hardness materials like 440C, MIM technology is particularly suitable.

corrosion resistance:

440C stainless steel is highly valued for its exceptional corrosion resistance, attributed to its high chromium content, typically comprising 16-18% of the alloy. Chromium forms a protective chromium oxide (Cr2O3) layer on the steel’s surface, which blocks the diffusion of corrosive agents like water, oxygen, and chloride ions. Additionally, 440C contains a higher carbon content compared to other stainless steels in the 400 series, enhancing its hardness, wear resistance, and corrosion resistance. These qualities make it suitable for various applications, including marine environments, chemical processing, and medical instruments.

Applications of MIM 440C STAINLESS STEEL example

Combining metal injection molding technology with 440C knife steel enables innovation in the knife manufacturing industry.

Utilizing metal injection molding technology to produce components with 440C knife steel allows for more intricate knife designs and improved production efficiency. 440C knife steel boasts excellent hardness, wear resistance, and corrosion resistance, making it an ideal choice for manufacturing high-quality knives. By combining these two technologies, knife manufacturers can produce knives with outstanding performance and durability, meeting the demands of various usage scenarios such as outdoor activities, kitchen use, and industrial applications.

In summary, the combination of metal injection molding technology with 440C knife steel provides knife manufacturers with more design flexibility and production advantages, enabling them to produce higher-performance knife products that meet the market demand for high-quality knives.

Conclusion

Stainless steel 440C stands out as a martensitic stainless steel renowned for its exceptional mechanical properties. JunKun employs metal injection molding (MIM) technology to produce top-notch 440C parts cost-effectively. Get in touch with us to kickstart your new MIM 440 project.