MIM (Metal Injection Molding) is a metal processing forming technology. It involves injecting a mixture of metal powder and its binder/plasticizer into a mold to form the desired shape. This process begins by blending the chosen powder with a binder, followed by pelletizing the mixture and then injecting it into the desired shape for forming.

- Mixing:Fine metal powder is mixed with thermoplastic polymers and wax binders in precise proportions. The mixing process takes place in a specialized mixing equipment (kneader) heated to a certain temperature to melt the binders. Mechanical mixing is commonly employed until the metal powder particles are uniformly coated with the binder. Once cooled, the mixture forms granules (referred to as feedstock) capable of being injected into the mold cavity.

- Injection Molding:The equipment and techniques for injection molding are similar to those used in plastic injection molding. Granular feedstock is fed into the machine, heated, and injected into the mold cavity under high pressure. Upon cooling, the formed green part is ejected from the mold. The binder is melted only at around 200°C, ensuring full fusion with the metal powder, allowing the entire process to proceed smoothly. Molds can be designed with multiple cavities to enhance productivity. Mold cavity dimensions must account for the shrinkage that occurs during the sintering process of the metal component. The shrinkage variation for each material is precise and well-known.

- Debinding:Debinding is the process of removing the binder from the molded components. This process is typically carried out in several steps. The majority of the binder is removed before sintering, leaving behind residual binder that can support the parts during entry into the sintering furnace.Debinding can be achieved through various methods, with solvent extraction being the most common. Components after debinding exhibit semi-permeability, allowing the residual binder to easily evaporate during sintering.

- Sintering:The debound components are placed into a high-temperature, high-pressure controlled furnace. The part is slowly heated under a protective gas atmosphere to remove residual binders. Once the binders are completely removed, the part is heated to a high temperature, causing the voids between particles to disappear as the particles fuse together. The part undergoes directional shrinkage to its designed dimensions and transforms into a dense solid. For most materials, typical sintered density is theoretically greater than 97%. High sintered density results in product performance similar to forged materials.

- Post-processing:Depending on specific requirements, some parts may require post-sintering surface treatments. Heat treatment can enhance the physical properties of the metal. Plating or coating can be applied to high-density materials. Welding or heat treatment techniques may also be provided.

MIM products typically characteristics:

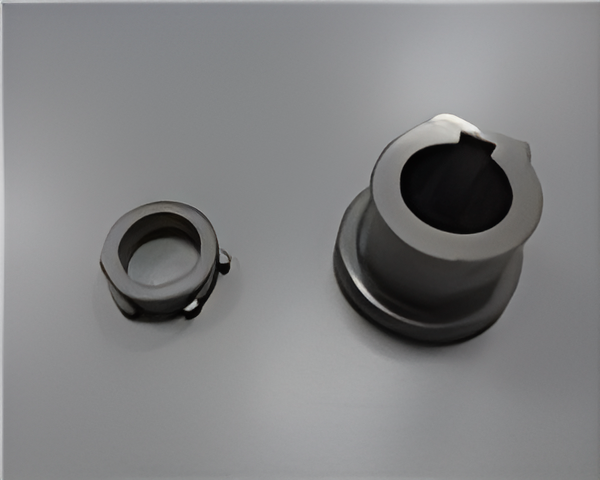

Complex Geometries: MIM enables the production of intricate and complex shapes that are difficult to achieve through conventional manufacturing methods.

High Density: Sintering at high temperatures results in MIM products with densities approaching that of wrought materials, leading to excellent mechanical properties.

Fine Surface Finish: MIM parts often exhibit a smooth surface finish, reducing the need for additional machining or finishing operations.

Tight Tolerances: MIM processes can achieve tight tolerances, ensuring precise dimensions and fit for the final product.

Material Versatility: A wide range of metals and alloys can be processed using MIM, offering versatility in material selection to meet specific application requirements.

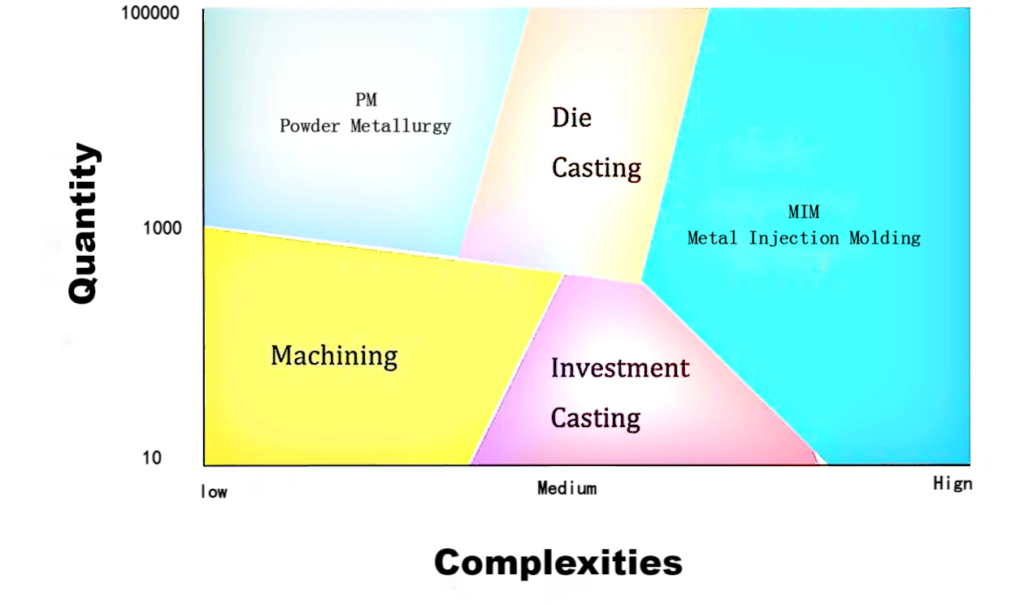

Cost-Effectiveness: MIM offers cost-effective solutions for producing small to medium-sized components in large quantities, thanks to its high production efficiency and minimal material wastage.

Excellent Mechanical Properties: MIM parts exhibit excellent mechanical properties, including high strength, hardness, and wear resistance, making them suitable for demanding applications across various industries.

These characteristics make MIM an attractive manufacturing solution for a wide range of applications, including automotive, aerospace, medical, and consumer electronics industries.

Expanding MIM Design Guidelines: Optimizing for Success

Design Do’s :Walls should be no thinner than 0.1mm (0.0039 in.)

Core out thick areas :Don’t design holes smaller than 0.1mm (0.00e9 inc) in diameter

Design with a flat surface, lettering and threads :Don’t design holes smaller than 0.1mm (0.00e9 inc) in diameter

Consider location of gates, ejector pins, and parting lines. :Dont design components over 12.55 mm (0.5 in.) thick and over 100 grams in mass Avoid designing sharp corners.

| Attribute | Minimum | Typical | Maximum |

|---|---|---|---|

| Component Mass (g) | 0.030 | 10-15 | 300 |

| Density | 93% | 98% | 100% |

| Max Dimension(mm) | 2 (0a.08 in) | 25(1 in) | 150 (6 in) |

| Min Wall Thickness (mm) | 0.025 (0.001 in)* | 5 (0.2 in) | 15 (0.6 in) |

| Tolerance (%) | 0.2% | 0.5% | 1% |

| Production Quantity | 1000 | 100,000 | 100,000,000 |

Typical Attributes Produced by the MIM Process

Ready to optimize your metal parts for success with Metal Injection Molding (MIM)? Contact us today to learn how our expertise in MIM design can help you achieve your manufacturing goals!