Introduction

When faced with the challenge of producing complex metal parts, you may consider various manufacturing methods such as machining, casting,or powder metallurgy. However, Metal Injection Molding (MIM) has brought a completely new manufacturing approach to this field. MIM technology enables the production of metal parts with complex shapes and precise structures. This technology not only expands the possibilities of manufacturing but also enhances production efficiency and part quality, thus garnering significant attention and favor from the manufacturing industry.

Compared with traditional metal processes technologies, Through MIM the production of complex parts can be achieved in a more economical and efficient manner without the need for multiple machining and assembly steps. This not only saves production time and labor costs but also reduces material waste and machining precision requirements. Additionally, MIM technology can improve the consistency and precision of parts, ensuring that each part has the same level of quality, thereby enhancing overall production efficiency and product quality. For industries that require the production of large quantities of complex parts, MIM technology is a reliable and feasible choice that can provide significant competitive .

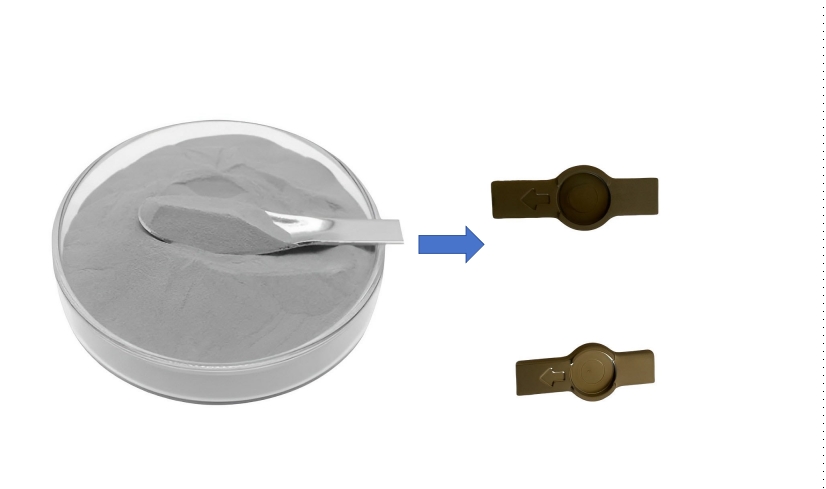

From Powder to Component

Metal powders used in MIM are prepared through special processes and typically have very fine particle sizes, usually below 20 microns. These fine metal particles, when mixed with binder materials can form parts with complex structures. The small size of the powder helps achieve high precision and intricate structures in the parts, laying an important foundation for the successful application of MIM technology.

Design and Fabrication of Molds

In the production process of MIM products, it’s important to consider the characteristics of significant shrinkage rates (around 15-18%) in both the raw materials and the processes involved. Furthermore, given that MIM technology is often applied to structurally complex products, the gravitational effects during injection molding, debinding, and sintering can vary based on the design features and positioning of the components. As a result, different dimensions and structural configurations may experience varying degrees of shrinkage, presenting challenges in size control and requiring careful consideration in mold design and fabrication.

Mixing Feedstock

In the manufacturing process of MIM products, fine metal powders are meticulously blended with thermoplastic polymers and paraffin-based binders in precise proportions. The mixture is heated to a specific temperature to melt the binder, which is then uniformly applied to the metal powder particles to create the raw material. The homogeneity of the mixture directly impacts its flowability, thereby affecting the parameters of the injection molding process and the ultimate density and properties of the material.

Injection Molding

The key to this process lies in the precise setting of parameters during injection molding, considering the diverse types of metal powders and variations in feedstock compositions. Any operational errors may result in product defects. Our technical team continuously optimizes the injection molding process by simulating the process, designing and manufacturing molds, and adjusting parameters. This optimization enhances injection capabilities and ensures uniformity throughout the injection process.

De-binding

De-binding refers to the process of removing the binder from the green parts through physical or chemical methods. This process transforms the mixture of metal powder and binder into pure de-binded parts (brown parts), retaining their original shape and structure while eliminating the binder. The de-binding process must ensure gradual removal of the binder from the tiny channels between the particles throughout the green parts, preserving their strength.

The essence of this process lies in controlling the residual binder in the parts. Inadequate de-binding may result in excessive residual binder, leading to product rupture during high-temperature sintering due to the decomposition and gasification of the binder. Conversely, excessive de-binding may cause adverse consequences such as metal oxidation and structural deformation. Therefore, selecting appropriate de-binding methods and controlling process parameters are crucial.

Sintering

The sintering process occurs within a controlled atmosphere in specialized furnaces. Debound parts are carefully positioned inside the furnace and gradually heated under specific pressure conditions and protective gas environment. This controlled heating allows for the gradual removal of residual binders. Once the binders are fully eliminated, the parts are subjected to high temperatures. During this stage, the particles within the parts fuse together, resulting in a reduction of gaps and a directional shrinkage towards the intended dimensions. Ultimately, this process transforms the parts into dense solid structures known as sintered parts, preserving their original shapes and structures. Typically, the sintered density surpasses 97%, ensuring that the final products exhibit performance characteristics akin to forged materials. Achieving optimal density in MIM parts involves precise control of parameters such as sintering temperature and duration to manage the inherent shrinkage rates effectively. The sintering process significantly influences the microstructure and properties of the end products, often playing a pivotal role in determining their overall quality.

Post-Processing

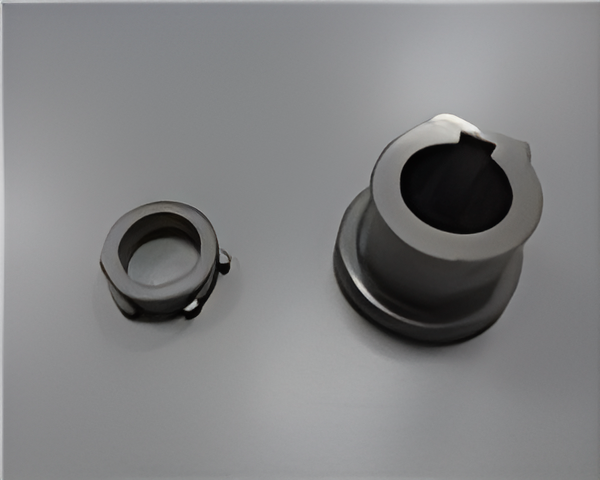

In the MIM process, the dimensional accuracy of sintered parts typically falls within ±0.3%. To mitigate any shrinkage discrepancies during sintering, ensure uniform product quality, and meet diverse customer requirements for higher precision dimensions, various applications, or specific surface finishes, post-processing becomes essential. This includes operations such as deburring, CNC machining, tapping, sandblasting, laser engraving, polishing, grinding, cleaning, and PVD coating.

Cost-Effective MIM Manufacturing

Generally, the manufacturing cost of MIM molds may be higher than plastic molds because they typically require the use of high-temperature resistant metal materials and involve a manufacturing process with higher precision and complexity. In comparison, the manufacturing cost of plastic molds may be lower because plastic materials are relatively inexpensive, and the manufacturing process is relatively simple.

Only small, precise, complex three-dimensional geometric-shaped metal parts with special requirements suitable for mass production are economically viable for Metal Injection Molding (MIM).

Only small, precise, complex three-dimensional geometric-shaped metal parts with special requirements suitable for mass production are economically viable for Metal Injection Molding (MIM).

What kinds of products suits for MIM?

Generally only small, precise, complex three-dimensional geometric-shaped metal parts with special requirements suitable for mass production are economically viable for Metal Injection Molding (MIM).

Batch production

Due to the need for molding through molds in the MIM process, and considering the associated costs of molds, MIM technology requires that metal parts reach a certain batch size to be economically viable.In general, the cost advantage of MIM process is typically realized for annual batch requirements of 10,000 pieces or more.

Dimensions

MIM technology is more suitable for small-sized metal parts.

The most typical size for MIM parts is around 25mm, with the maximum size not exceeding 150mm.

Weight

MIM technology is more suitable for lightweight metal parts.The typical weight of MIM parts is usually around 10 to 15 grams, with the most cost-effective range being less than 50 grams. The maximum weight typically does not exceed 300 grams.

Thickness

Typically, MIM (Metal Injection Molding) parts have a thickness ranging from 0.5 millimeters to 6 millimeters. However, this can vary based on the specific requirements of the part and its intended application.

Typically, MIM (Metal Injection Molding) parts have a thickness ranging from 0.5 millimeters to 6 millimeters. However, this can vary based on the specific requirements of the part and its intended application.

Shape

Metal Injection Molding parts are suitable for complex three-dimensional geometries with features such as external grooves, external threads, tapered outer surfaces, intersecting through-holes, blind holes, recesses, keyways, reinforcing ribs, and surface patterns. However, for simpler shapes, processes like sheet metal stamping, forging, and powder forming may offer more economical value.

Metal Performance Puzzle

MIM products can achieve a relative density of over 95%, comparable to forged parts, even in solid-state sintering. However, compared to forging, MIM parts’ drawbacks mainly lie in their residual porosity and microstructure. The unavoidable presence of a certain level of porosity in the MIM process may affect the mechanical properties of the parts, such as impact and fatigue strength.

MIM materials can be compared with traditional materials in several aspects:

Strength and Hardness: MIM materials typically exhibit excellent strength and hardness, This enables MIM parts to perform exceptionally well under pressure and loads.

Density: The density of MIM materials usually approaches theoretical density, resulting in parts with high density and tight structure, thereby enhancing their mechanical properties.

Surface Quality: Due to the characteristics of the MIM process, MIM parts typically have higher surface finish and precision, meeting the high requirements for surface quality.

Corrosion Resistance: MIM materials generally offer good corrosion resistance, enabling parts to operate stably for extended periods in harsh environments.

Cost-effectiveness: Compared to traditional machining processes, the MIM process typically achieves higher material utilization rates and produces less waste, thus reducing manufacturing costs.

The MIM process shares many common characteristics with plastics. Both are conducive to hollow and thin-walled shapes, as well as tapered and generally elongated geometries. Generally, if a part is feasible in plastic, it can be achieved through MIM, although this may not be cost-effective.

All you need is to provide us with the drawings of your product, and we can conduct a comprehensive analysis to determine if it is suitable for the MIM . Our professional team has extensive experience and technical expertise to accurately assess the structural characteristics and manufacturing requirements of your product and provide the best recommendations.we are committed to providing customers with high-quality and high-performance metal parts. Our professional advantages include precision mold design and manufacturing, optimization of production processes, meticulous material selection, and quality control. Whether your product is small or complex, we can tailor the optimal solution to maximize product quality and production efficiency.

Using MIM technology, you can easily achieve the production of complex geometric structures and precision parts, whether they are hollow, thin-walled, or elongated in shape. Through MIM, not only can you save assembly time, but you can also reduce production costs, making your project more competitive.